Let’s break down the anatomy of a concrete coating failure—and how it could have been avoided with a true garage floor epoxy system.

Imagine this:

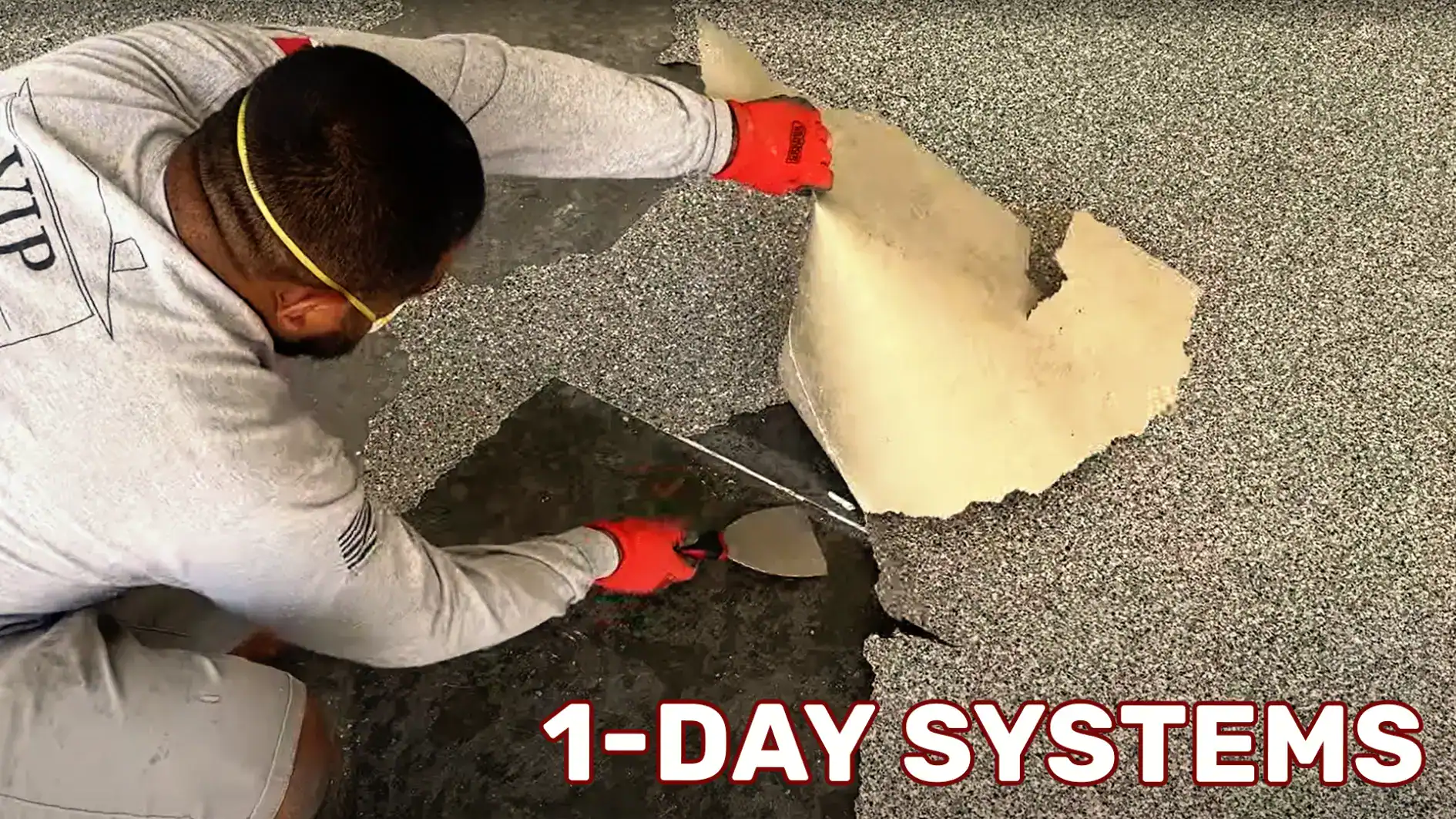

A Colorado Springs homeowner books a garage floor coating after seeing a tempting promise—“4 to 20 times stronger than epoxy!” The 1-day install looks great at first: clean, shiny, and done fast. But within a few months, the surface starts to bubble. Then it peels. And by next year, large sections are delaminating from the concrete. What happened?

Stage 1: The Misleading Pitch

The 1-day company sells their system as “stronger than epoxy.” But what they don’t say is that they’re comparing it to a cheap, water-based DIY epoxy kit, not the industrial-grade garage floor epoxy used by professionals.

Their product is a fast-curing polyurea or polyaspartic applied directly to concrete. It dries quickly—but that doesn’t mean it’s built to last. It lacks the layered protection, moisture control, and system thickness that define real durability.

Stage 2: Skipping Moisture Mitigation

In Colorado Springs, concrete slabs can trap moisture from below—even in dry seasons. One of the most common reasons for coating failure is moisture vapor rising through the slab.

1-day systems may test for moisture, but they often skip the fix: a 100%-solids epoxy primer that actually blocks vapor transmission. Without it, the coating may look fine for a while… until the first signs of blistering appear.

Stage 3: Thin System, No Second Line of Defense

To finish the job in a single day, these companies typically apply:

- One coat of polyaspartic or polyurea directly to the concrete

- One clear topcoat (typically less than 100%-solids)

- No full-flake buffing, no second topcoat

This creates a thin, fast system that lacks long-term impact resistance. Once wear or moisture gets through, there’s no backup layer to prevent failure.

Stage 4: Delamination and Regret

As vapor pushes upward, the thin topcoat bubbles. Abrasion from tires or tools exposes the concrete. The floor peels, and the only solution is costly repair or a full replacement.

The homeowner remembers that “4 to 20 times stronger” claim—and realizes it was just a slogan, not a system.

The Solution: Garage Floor Epoxy Built for Colorado Conditions

At Garage Floor Coating of the Front Range, we prevent all of the above by installing a true garage floor epoxy system that includes:

- A 100%-solids epoxy primer for moisture mitigation (ASTM F3010 compliant)

- A full-flake broadcast layer for durability and appearance

- Two coats of polyaspartic topcoat for chemical, UV, and abrasion resistance

And we back it with a lifetime warranty against moisture-related coating failure.

Get your free consultation today and skip the failure story entirely. Your floor deserves better than shortcuts and slogans.